Building a portable air cleaner

How I built a simple dust cleaner from scrap wood.

Unless you strictly use hand tools in your shop, more power to you, you probably make a lot of fine dust and really should have an air cleaning system.

Air or dust cleaners remove most of the fine (and most dangerous) dust from the air you breath, and they run much quieter than dust collectors.

You can buy a shop air cleaner but making your own is simple and saves a decent amount of money, especially if you are making multiple. This is not to be confused with an air purifier, a shop air cleaner like this only removes a fraction of the dust that comes through it depending on many things like the fan power, the filters used, the air flow dynamics, leakage points, etc. That said, even a simple system like the one described in this post removes a large amount of dust in a small shop especially if left running and others have shown these simple box fan filters perform comparably to expensive products.

There are many ways to make one of these units using some combination of a fan blowing air through or into a filter and there are tons of resources on this that go into more depth and details. Also, the box aesthetics I decided on might be over the top for your needs so just take what is useful from this post and modify the design.

The simplest method if you are in a pinch or don't feel the urge to make something is to simply tape a standard home furnace/AC filter onto the back of a box fan. The major downfall is that some of the dust will be blown out and around the filter as opposed to directed through it.

I made this air cleaner about two years ago and unfortunately didn't take many pictures but this post describes the most important concepts and should help if you decide to build one.

A box that holds a fan and filters

The idea is to use a cheap box fan to suck up dusty air and deposit the dust into a filter, thereby removing it from the air in your space.

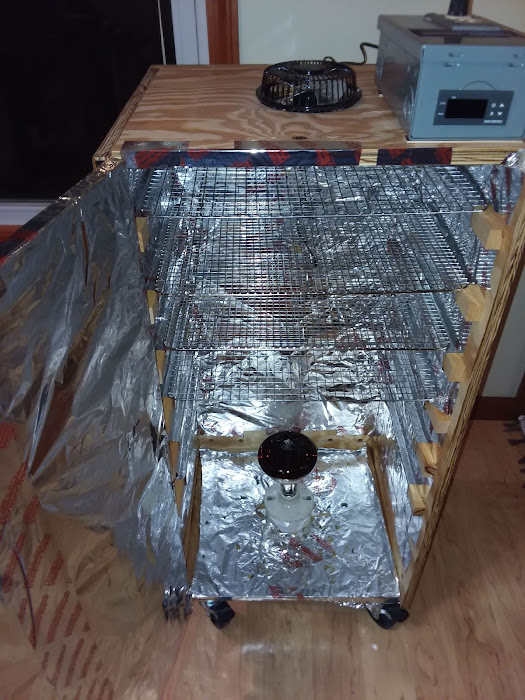

From some research I decided the most efficient build would be to put a less resistant (more open mesh) filter behind the fan to catch larger incoming particles, leave a few inch gap to improve the internal flow, followed by a finer mesh filter on the outflow site. The box was made with grooves that hold standard furnace filters from all sites to reduce air getting around the filters. The final result looks like this:

Details of the build

A few pieces of scrap plywood strips were also situated inside the box to hold the box fan securely. Holes were drilled in the top (a removable lid) and bottom of the box for the fan knob and cord respectively. I took a scrap metal and bent it down to hold the cord where it enters the box to avoid it being pulled out if the box was accidentally yanked.

The internal box measurements need to be laid out to hold the widths of the fan and the air filters.

Almost all of this project was assembled with a brad nailer and sometimes with glue, the walls of the box were joined to the bottom using a dado for added strength. There are many other options.

For this build, the removable top had spacers that were precisely placed to align with those on the side walls for holding in the front and back filters and box fan.

Lastly, four scrap blocks of wood were slightly rounded and attached to the bottom as "legs", they help with moving the fan, protecting the floor, and protecting the cord. The entire thing was finished with some boiled linseed oil.

I admire this article for the well-researched content and excellent wording. I got so involved in this material that I couldn’t stop reading. I am impressed with your work and skill. Thank you so much. Read more info about Air Source Heat Pump Installation

ReplyDeleteSie haben diesen Beitrag sehr sorgfältig verfasst. Wartungsvertrag für Klimaanlagen in Norddeutschland Die Fülle an Informationen ist beeindruckend und der Artikel ist sehr hilfreich für uns. Teilen Sie bitte weiterhin solche Artikel. Vielen Dank!

ReplyDelete