Thoughts from replacing a furnace and adding a split AC in a manufactured home

A detailed description of what I learned from replacing a mobile home furnace with a full size furnace and split AC unit.

Disclaimer!

I take no responsibility for anything that you do and do not consider anything in this post as advice. I am not a licensed HVAC technician. Before doing any HVAC projects refer to your local building codes and permitting laws and consult a licensed professional. You may or may not be permitted to do any of this work yourself if you are not licensed. The goal of this post is to give you an idea of what it takes to do this sort of job and some things to keep in mind perhaps to help you make sure your contractor is doing an adequate job or at least so that you can follow along. Perhaps this information may help you save some money, but this is NOT a DIY how-to guide!

Not too long ago the furnace in my manufactured home had a gas build up that resulted in a small explosion and bending of the heat exchanger. Fortunately it did not cause a leak and we were able to shut off the gas for the season, it was 22 years old and it was time to replace it. The home also did not have air conditioning so it was a good time to put in a split system central air conditioning unit along with the new furnace. This post will run through the general process of removing the old furnace and the install of a new AC and furnace. The details of some steps are left vague as they were done by a contractor although I will mention all the major steps involved in the process.

Tear-out the old furnace

Be sure that the electric power to your unit and gas flow are off. This typically involves switching your breaker and turning off your gas valve to your furnace and the home's main gas valve. A contractor will verify that these are off with a voltage detector and gas leak detector.

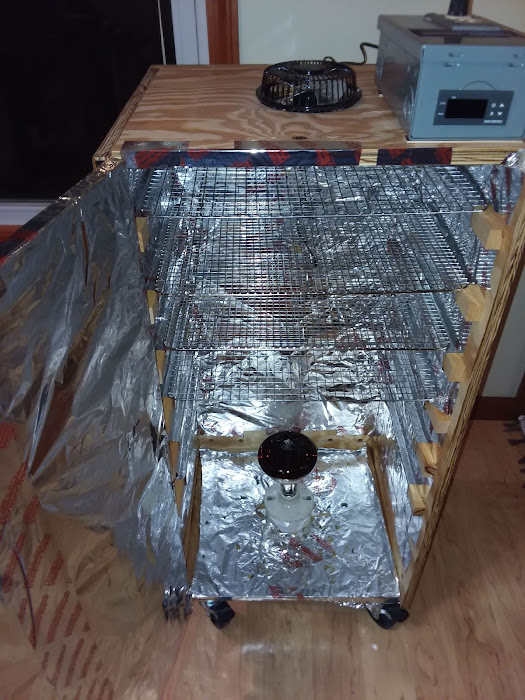

Removing the old furnace requires some elbow grease and patience. A crow bar and a drill are important tools here. In our case the furnace was located in a "closet" and was fastened securely to the flue and sealed to the floor with silicone. As such there was minimal open space on the sides of the unit- just a few inches. Ultimately the unit had to be removed slowly by disassembling it piece by piece until the empty frame could be lifted and hauled out. If your unit is not enclosed in a small space then you will have an easier time at this stage. You will likely need a truck or trailer to haul the waste material to the dump if your contractor does not do this for you. I ended up salvaging many sheet metal screws from the unit which have later been put to good use. You may also be able to get some cash from scrap metal or reuse sheet metal, etc. Of course, the blower fan and motor are of use for some DIY shop or home projects, for me this includes building a dust collector. Once torn out you can take the time to clean the supply plenum or duct to which your system outflows and then seal it from dust while the project is underway.

Make concrete slab for condenser

We had a small concrete slab made for the AC condenser just outside of the house in a location that is ideally as close as possible to the AC coil and blower inside. This may be something you can help with. In picking the slab location your contractor, the most critical things are that drain lines and the refrigerant line set for the AC will have no major obstacles while keeping the distance short to reduce the energy and heat loss of your system. It is important to use the appropriate concrete for small slabs, and it is a good idea to make it a bit larger than your condenser to protect it from soil and vegetation. Our slab was reinforced with steel mesh and lain over compacted angular gravel. As with any concrete work be sure to finish the surface and let it dry properly (not too fast) for maximum strength. Be sure that the slab forms and finished surface are level as well otherwise the condenser may not function properly.

Prepare connections and layout

The connection from your AC or furnace to your duct will vary, in our case the supply air flows into ducts that run beneath the home. From what I understand, this is common in manufactured homes. Other homes are designed based on climatic settings and architectural considerations and may have return air coming in from the bottom of the furnace/AC system and supply air leaving from the top of the system into ducts in the ceiling. In either case the connection will typically be a sheet metal plenum or some sheet metal ductwork. The condensate drains from the new furnace and AC will also need space if there was no prior drain, a PVC pipe with a trap installed will generally be threaded or glued to new high efficiency gas furnaces and all AC units to drain condensate water. In our case the drain runs beneath the floor joists and out the wall to drain above the ground. A refrigerant line set consists of two copper pipes, for return and supply flow, will need to run from the condenser outside on the slab that was created to the AC coil that is located downstream of your blower, In our case beneath the gas furnace. It is important that the copper pipes in the line set are not bent or have any serious kinks, therefore laying out the location of the line set path so that it does not contain sharp bends is important. Another thing to consider here is that line sets typically come in predetermined lengths if not specially ordered therefore you can save some money (and energy) by figuring out the shortest length that corresponds with one of these lengths (e.g. 25 ft) by determining the location for the condenser and connection path. It is important to lay this out before you move on to the installation.

Install return air grill

You may already have a return air plenum for your previous system. In our case we did not because the previous unit was a mobile home furnace that received combustion air from within the house from the front of the unit. We replaced this unit with a standard gas furnace that required a supply air connection of filtered air. What we did was install a return air grill in the non-load bearing wall behind the unit. This will later be attached to the return air intake on the furnace unit with a flexible insulated HVAC duct. The square shaped grill needed to be attached to a circular duct therefore we manufactured a small box from sheet metal to couple these together. Any skilled contractor can manufacture custom ductwork to fit these situations on the spot. Here it is important to refer to your units air flow to determine that size of return air filter and corresponding ductwork to attach to the furnace. If your return air filter and connecting ducts are too small this may greatly reduce the efficiency of the HVAC system!

Install coil, furnace/blower, and flue

Connecting the new units will depend on your system, in this case our system is downward flowing so the AC coil goes on the bottom and connects to the supply ducts while the furnace and blower are above. The top of the unit connects to the return air that was installed in the adjacent wall, in the upper portion. The top of the unit also has PVC connections to the roof flue for combustion air. The installation of the AC coil will attach to the supply air duct. HVAC silicone caulk is used to seal the furnace and AC units together, they need to be carefully aligned when they are stacked. After the AC and furnace are connected to the supply duct system/plenum and each other they will need to be connected to the ductwork that makes up your return air. In our case this was a 20 x 20" grill and insulated flexible duct. Be sure that any new ductwork is air tight on the return side to minimize dust entering the unit, small gaps in the flexible duct connections may be sealed with HVAC tape. Next the connections for the furnace combustion air need to be made, typically through a roof stack. If you need to run a new flue stack to the roof be sure that the contractor has experience and is able to correctly install flashing around the new flue without damaging the roof material. Otherwise you may be able to reuse the old flue stack by connecting into it from the bottom if you did not damage it when removing the original unit. As with the return air, it is critical to use the right size pipes (PVC in our case) for combustion and discharging outside air.

Run the refrigerant line set and drains

Now that all the units are in place it is time to connect the refrigerant line set to the coil and run condensate drains from the furnace and AC coil. The refrigerant line set runs from the AC coil to the location of the condenser slab, the location that it exits the home should be in line with the location of the connection on the condenser that you will put on the concrete slab later. Similarly, the layout for the line set should result in the connection coming into the home so that it does not need to be bent sharply and ends near the AC coil. Next the condensate drains from the furnace and coil need to run somewhere to drain, in our case they were connected using PVC pipe which ran beneath the sub floor where we placed a trap in the line and then ran out to the bottom of the siding in the skirting to drain a few inches from the foundation. The drain was attached to the bottom of the floor joists, it should not be left unsupported. Similarly for the line set, the high pressure in the system can cause the line set to move with the condenser pump activates and shuts off, therefore keep the line set away from any sharp surfaces that it may abrade into. Minimize damage in the homes siding by drilling the exit homes in strategic locations and use a small diameter bit to locate the spot before drilling the final large hole for the lines. The line set is insulated to keep energy loss to a minimum, the connection outside to the condenser should be as close as allowed to the home to also minimize energy loss. Any exposed part of the refrigerant line that flows cold fluid from the condenser should be wrapped in thick (e.g. 10 mil) HVAC line set tape. Lastly, seal with caulk or foam where the lines exit the home's exterior.

Electrical work for condenser, furnace, and brazing

A licensed electrician may need to add a dedicated circuit to your AC condenser if it is a new system as was my case. It is a good idea (if not required by your local code) that a separate shutoff switch is installed neat the condensor (outdoors) for the unit. Also, they should mount the wiring with the correct outdoor conduit. Similarly, electrical connections need to be made for the furnace and thermostat. Next the line set (which carries the refrigerant) needs to be connected to the AC coil and condenser. Typically copper connections are brazed using high temperature (e.g. from an oxygen acetylene torch) and flux. A good HVAC contractor who has read up on the newest and best methods will put a low pressure flow of nitrogen gas in the line set while brazing the connections in order to purge oxygen from inside the pipe. This practice reduces oxidation that occurs inside the pipe that would otherwise leave behind carbon particles and soot in the line that could damage the AC system or reduce its efficiency or durability. Next the system will be pressurized with refrigerant fluid to a certain level or pressure depending on the system and check for leaks by any drops in pressure using a gauge attached to the condenser. At this point the blower and AC system can usually be turned on and tested as the only thing left to do is connect the gas to the furnace.

Gas connection for furnace

The furnace needs to be reconnected to the gas line using the same diameter iron gas line that the home uses or larger. We had a safety vale installed that replaced our old simple gas valve before it connects to the gas furnace. Be sure that the contractor installs a trap in the gas line to reduce debris and dust that may otherwise enter the furnace. The threaded iron pipe should be well tighten and utilize gas joint pipe compound, and finally tested for leaks. Congratulations!

Other tips

You might be able to save money by working with your contractor and permitting office and doing some of these steps yourself- maybe not. Either way you can also save by asking contractors if you can help search for the best units to buy from a HVAC wholesaler.

Excellent post. I really enjoy reading and also appreciate your work.Split System Installation Services Melbourne This concept is a good way to enhance knowledge. Keep sharing this kind of articles, Thank you.

ReplyDeleteI just need to say this is a well-informed article which you have shared here about hoodies.air duct cleaning elk grove village It is an engaging and gainful article for us. Continue imparting this sort of info, Thanks to you.

ReplyDeleteThis information is so useful and informative which you have shared here. It is beneficial for beginners to develop their knowledge. It is very gainful information. Thanks for sharing Duct Cleaning Services in Kuala Lumpur.

ReplyDeleteYou've posted a very informative post here. This article provided me with some useful knowledge. Thank you for sharing about air conditioner calgary. Keep up the good work.

ReplyDeleteThanks for publishing such great information. You are doing such a great job. This information is very helpful for everyone. Keep sharing about duct installation chicago. Thanks.

ReplyDeleteI generally check this kind of article and I found your article which is related to my interest.Air Conditioning Tent Genuinely it is good and instructive information. Thankful to you for sharing an article like this.

ReplyDeleteYes, you can add an air conditioner to a forced-air heating system. However, it is a complex process. Of course, we’ll say this about any air conditioning or heating installation. There are many factors that go into matching the right system to the right home take sizing for instance. If your home already has ductwork for a forced-air furnace in place, then adding central air conditioning will be a bit easier. Professional technicians will help for furnace repair Grand Forks with all care.

ReplyDeleteHome owners are often faced with the decision to replace their furnace and/or air conditioning system. Usually many are not faced with having to install both at the same time. Choosing Martens Plumbing & Heating means you’re working with a factory-trained installer who follows strict guidelines and guarantees your satisfaction 100 percent. Each part is carefully inspected and installed, every connection is secure, and we test your system to guarantee it’s working exactly as it should be.

ReplyDeleteThe delightful article you have posted here. This is a good way to increase our knowledge.Led Televisions For Sale Online Pakistan Continue sharing this kind of articles, Thank you.

ReplyDeleteThe context of this content is really good. Thank you for sharing this type of awareness with us. In this article, you shared much informative knowledge on multiplication activities. Take look at this tooAir Duct Cleaning fort st john . Thanks!

ReplyDeleteInteresting stuff to read. This blog regarding Ac Installation in Prabhat Road is truly helpful for me. Thank you for sharing such an informative blog with us.

ReplyDeleteIt is what I was searching for is really informative.Furnace Installation Edmonton It is a significant and useful article for us. Thankful to you for sharing an article like this.

ReplyDeleteI simply needed to say this is an exquisitely formed article as we have seen here. I got some information from your article and furthermore it is a huge article for us. Gratitude for sharing an article like this.Replacement Furnace in Orleans

ReplyDeleteThe information and advice in this post are excellent. Continue providing us with these kinds of articles; it will enable us to gain a better understanding of furnace installation services. While each of the advantages you stated is significant, your family's safety and comfort at home should come first. A dependable furnace will keep your family warm and comfortable throughout the winter. When your furnace is professionally installed, it should work flawlessly for a while.

ReplyDeleteFor many homeowners, this can be more convenient, especially if they’re worried they’ll forget to schedule Regular Furnace Maintenance . You have shared huge information about it . Your new valuable key points are simply much a person like me and extremely more to people's furnace workers. In either case, you can save money by asking contractors if you can help them find the finest units to purchase from an HVAC wholesaler.

ReplyDeleteThis blog shows quite good knowledge about furnaces. There are four types of furnaces such as natural gas, oil furnace, propane, and electric furnaces. According to me electric furnaces are good because they are more economical rather than others. We should give importance to the safety part of the furnace so we should go for regular maintenance by the furnace repair company.

ReplyDeleteI think this blog has planned really well that how to put a furnace really easily.

ReplyDeleteThis article contains a lot of huge information. I'm surprised by the idea of the information and moreover it is a productive article for us, Gratitude for share it.Professional Air Duct Cleaning Service Hollywood

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteGreat post, John! Your detailed experience with replacing a furnace and adding a split AC in a manufactured home offers valuable insights. It's essential to understand local codes and regulations and consult professionals for complex tasks. This ensures safety and compliance. Seeking professional electrical services can help ensure everything is up to code and safely installed.

ReplyDeleteThis post contains a lot of important details. I am amazed by the quality of the info as well as also it is a useful post for us; many thanks for sharing it. watlow 4ft

ReplyDeleteGreat insights on replacing a furnace and adding a split AC in a manufactured home! It’s helpful to understand the considerations involved in making such upgrades. Thanks for sharing your experience!

ReplyDeleteCool

ReplyDeleteI am glad that I came here and I can gain more information about this. You have written this article very factual which is understandable for everyone, Thanks for share it. Carrier ac dealer

ReplyDeleteExcellent post. I really enjoy reading and also appreciate your work.Kinghome Heat Pump Canada This concept is a good way to enhance knowledge. Keep sharing this kind of articles, Thank you.

ReplyDeleteI admire this article for the well-researched content and excellent wording. I got so involved in this material that I couldn’t stop reading. I am impressed with your work and skill. Thank you so much. Read more info about Heating Services in San Jose Cost

ReplyDeleteExperts in furnaces for aluminum process systems, offering advanced melting, holding, and heat treatment furnaces. Our systems ensure consistent quality, energy efficiency, and smooth production for aluminum casting and recycling industries. Manufacturer of HEAT TREATMENT FURNACE

ReplyDeleteIt is truly a well-researched content and excellent wording. I got so engaged in this material that I couldn’t wait to read. I am impressed with your work and skill. Thanks. Read more info about Carbon Filtration Service for Water in San Jose Ca

ReplyDeleteHervorragender Beitrag. Ich lese Ihre Artikel sehr gerne und schätze Ihre Arbeit. Wartungsvertrag für Klimaanlagen in Norddeutschland Dieses Konzept ist eine gute Möglichkeit, Wissen zu erweitern. Teilen Sie bitte weiterhin solche Artikel. Vielen Dank!

ReplyDeleteHervorragender Beitrag. Ich lese Ihre Artikel sehr gerne und schätze Ihre Arbeit sehr. Klimaanlagensysteme Dieses Konzept ist eine gute Möglichkeit, Wissen zu erweitern. Teilen Sie bitte weiterhin solche Artikel. Vielen Dank!

ReplyDeleteExcellent knowledge, You are providing important knowledge. It is really helpful and factual information for us and everyone to increase knowledge. Continue sharing your data. Thank you. Read more info about Water Softener Installation Services in Toronto

ReplyDeleteI generally check this kind of article and I found your article which is related to my interest.Carbon Filtration Service for Water in San Jose Ca Genuinely it is good and instructive information. Thankful to you for sharing an article like this.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteDas ist genau das, wonach ich gesucht habe, und es ist wirklich informativ. Klimaanlage für Wohnung in Hamburg Dies ist ein wichtiger und nützlicher Artikel für uns. Vielen Dank, dass Sie einen solchen Artikel geteilt haben.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteEs handelt sich um einen wirklich gut recherchierten und hervorragend formulierten Text. Ich war so gefesselt, dass ich es kaum erwarten konnte, weiterzulesen. Ich bin beeindruckt von Ihrer Arbeit und Ihrem Können. Vielen Dank. Lesen Sie mehr über Klimaanlage für Vahnung in Hamburg

ReplyDelete